PMN-PT

As a new type of piezoelectric material, lead magnesium niobate lead titanate (PMN-PT) [Pb (Mg1/3Nb2/3) O3] (1-x) - [PbTiO3] x single crystal material has the characteristics of high voltage electrical constant, large electromechanical coupling coefficient, high dielectric constant, low loss, excellent nonlinear optical performance and pyroelectric performance. In particular, the piezoelectric performance is about 10 times higher than that of ordinary piezoelectric materials, making it more widely used than traditional PZT piezoelectric ceramics, It can not only meet the application needs and become the core material of a new generation of high-performance piezoelectric transducers, nonlinear optical devices and photoelectric detection devices (such as infrared detectors), but also provide a good research carrier for researchers.CasCrysTech (CCT) provides high quality PMN-PT crystals upon request from customers.

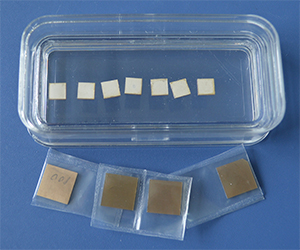

CCT provides different specifications of lead niobium magnesium titanate PMN-PT crystals.

Uses/Applications

It can be used in a wider range of applications than traditional PZT piezoelectric ceramics. It can not only meet the application needs and become the core material of a new generation of high-performance piezoelectric transducers, nonlinear optical devices and photoelectric detection devices (such as infrared detectors), but also provide a good research carrier for researchers.

Features/Benefits

The phase transition temperature and coercivity field of the developed product are improved.

Electromechanical coupling coefficient k33 up to 0.94; Field induced strain s > 1.7%.

The piezoelectric coefficient d33 is about 4 ~ 5 times higher than PZT, and the dielectric loss is 1 ~ 3 lower.

-

Parameters

Formula

[Pb(Mg1/3Nb2/3)O3] (1-x)- [PbTiO3] x, X=0.24-0.40

Structure

Tetragonal

Lattice constant

a=4.024 Å (R3m)

Melting Point

1280℃

Growth method

Bridgman

Density

8.1 g/cm3

Hardness

3.5

Thermal Expantion

10.4x10-6/KB

Dielectric constant (polarization)ε

4000-5500@1KHz

Piezoelectric constantd33

1200-1500;1500-2000;2000-2500 pC/N

Curie Temperature

135-150 ℃

Phase Changing Temperature

50-90℃(Monoclinic-etragonal phase transition)

Electric-Mechanic coupling constant

K33(L-mode):˃ 92%; Kt(T-mode):59-62%;

K33(Beam mode)84-88%

Coercive electric field

2-2.5 kv/cm

Orientation

<100>,<110>,<111>

Orientation tolerance

±0.3-0.5°

Size

5x5mm, 10x10mm, 20x20mm,Dia50.8mm.

Can be customized.

Thickness

0.5-10mm

Package

Class 100 clean bag, in single wafer containers, under a nitrogen atmosphere.

-

According to customers requirements.