LaAlO3

Lanthanum aluminate (LaAlO3) single crystal is currently the most important single crystal material for large-scale high-temperature superconducting thin film substrates. Generally grown by Czochralski method, single crystals and substrates with diameter of 2 inches or more can be obtained. It is well matched with YBaCuO and other high-temperature superconducting materials and lattices, with low dielectric constant, low microwave loss and good thermal stability. Lanthanum aluminate has broad application prospects in the fields of electronics, optics and energy.

For example, in the field of electronics, lanthanum aluminate can be used as a thin film dielectric layer to manufacture ceramic microwave dielectric devices with high dielectric constant; In the field of optics, lanthanum aluminate can be used as a highly transparent ultraviolet light barrier film, which is widely used in optoelectronic devices such as lasers and photoluminescent devices; In the field of energy, lanthanum aluminate can be used as the cathode material of fuel cells to improve the electromotive force efficiency of fuel cells.

Therefore, lanthanum aluminate has broad application prospects and will be widely used in the future.

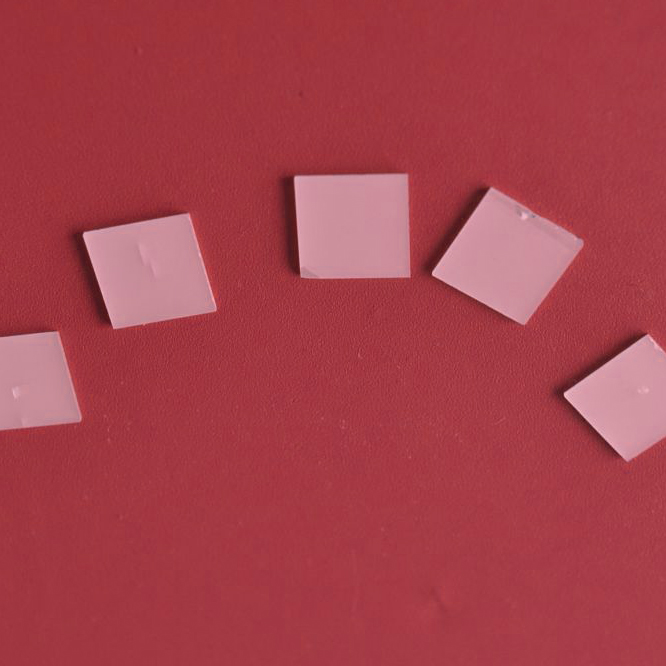

CasCrysTech (CCT) provides high quality lanthanum aluminate (LaAlO3) crystal which can be customized upon customer's requirements.

Uses/Applications

Making high-temperature superconducting microwave electronic devices (such as high-temperature superconducting microwave filters in telecommunication).

Features/Benefits

Matches well with high-temperature superconducting materials and lattices such as YBaCuO;

Has low dielectric constant and low microwave loss.

-

Crystal Structure

M6(normal temperature)

M3(>435℃)

Lattice Constant

M6 a=5.357A c=13.22 A

M3 a=3.821 A

Melting Point

2080℃

Density

6.52(g/cm3)

Mohs Hardness

6-6.5(mohs)

Thermal Expansion

9.4x10-6/K

Dielectric Constants

ε=21

Secant Loss(10GHz)

~3×10-4@300k,~0.6×10-4@77k

Color and Appearance

To anneal and conditions differ from brown to brownish

The polished substrate has natural twin domains.Chemical Stability

Room temperature is not dissoluble in minerals, the temperature is greater than 150 ℃ in soluble h3po4

Characteristics

For microwave electron device

Growth Method

Czochralski

Dimension

10x3mm,10x5mm,10x10mm,15x15mm,20x15mm,20x20mm

Ф15,Ф20,Ф1″,Ф2″,Ф2.6″

Thickness

0.5mm,1.0mm

Polishing

One side or two sides

Orientation

<100> <110> <111>

Crystal Plane Orientation Accuracy

±0.5°

Edge Orientation Accuracy

2°(Special requirements can reach within 1°)

Bevel Wafer

According to specific requirements, wafers with edge-oriented crystal planes inclined at a specific angle (inclination angle 1°-45°) can be processed.

Surface Roughness

Ra≤5Å(5×5µm)

Package

Class 100 clean bag, Class 1000 super clean room

-

Dimension

10x3mm,10x5mm,10x10mm,15x15mm,20x15mm,20x20mm; Ф15,Ф20,Ф1″,Ф2″,Ф2.6″.Thickness

0.5mm,1.0mm