YSZ

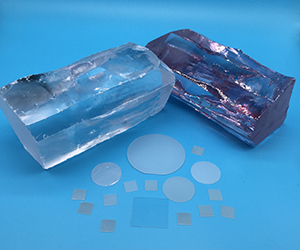

Zirconia(ZrO2) single crystal wafer is one of the most early high temperature superconducting substrate. Because Zirconia needs to be dopped with yttrium to stable its structure, normally the dopped yttrium dopped Zirconia(YSZ) single crystal is used. The mechanical stability and chemical stability of YSZ is excellent, and it has relatively lower price, which is especially applicable in making positive film.CasCrysTech (CCT) provides high quality Zirconia(ZrO2) crystals upon request from customers.

Uses/Applications

Zirconia(ZrO2) single crystal wafer is one of the most early high temperature superconducting substrate. Because Zirconia needs to be dopped with yttrium to stable its structure, normally the dopped yttrium dopped Zirconia(YSZ) single crystal is used.

Features/Benefits

The mechanical stability and chemical stability of YSZ is excellent, and it has relatively lower price, which is especially applicable in making positive film.

-

Crystal Structure

Cubic

Growth Method

Electric-Arc fusion Method

Lattice Constant

a=5.147Å

Melting Point

2700℃

Density

6.0 (g/cm3)

Mhos Hardness

8-8.5 (mohs)

Purity

99.99%

Thermal Expansion

10.3×10-6/K

Dielectric Constant

ε=27

Dimension

10×3mm, 10×5mm, 10×10mm, 15×15mm, 20×15mm, 20×15mm

According to customer needs, substrates with special orientation and size can be customized.

Thickness

0.5mm,1.0mm

Dimensional Tolerance

<±0.1mm

Thickness Tolerance

<±0.015m, ±0.005mm for special needs)

Polishing

One side or two sides

Orientation

<100>、<110>、<111>etc.

Orientaion Tolerance

±0.5°

Edge Orientation Accuracy

2°(Special requirements can reach within 1°)

Chamfered Wafer

According to specific requirements, wafers with edge-oriented crystal planes inclined at a specific angle (inclination angle 1°-45°) can be processed.

Package

Class 100 clean bag, Class 1000 super clean room

-

Dimension

10×3mm, 10×5mm, 10×10mm, 15×15mm, 20×15mm, 20×15mm

Customize size and crystal orientation upon request.

Thickness

0.5mm,1.0mm

Dimensional Tolerance

<±0.1mm

Thickness tolerance

<±0.015m, ±0.005mm for special needs)