MgAl2O4

Magnesium aluminate (MgAl2O4) can be used as the substrate substrate of III-V nitride device thin film, and is also widely used in acoustic wave and microwave devices and fast IC epitaxial substrates. In addition, it has a good lattice matching with epitaxial silicon thin layer. The self-doping of aluminum atoms in the epitaxial silicon thin layer is small, the thermal stability is good, and the expansion coefficient of silicon is relatively close, the hardness is small, the processing performance is better, etc., so it can be used as a high-quality insulating lining for ultra-high-speed large-scale integrated circuits One of the bottom materials. At present, we can provide twin-free, crystal-domain-free, and ultra-smooth high-quality substrate substrates with a maximum diameter of 2 inches (FWHM<50 arcsec, roughness Ra<0.5 nm).

CasCrysTech (CCT) provides high quality Magnesium aluminate (MgAl2O4) crystals upon request from customers.

Uses/Applications

Magnesium aluminate (MgAl2O4) can be used as the substrate substrate of III-V nitride device thin film, and is also widely used in acoustic wave and microwave devices and fast IC epitaxial substrates.

It can be used as a high-quality insulating lining for ultra-high-speed large-scale integrated circuits One of the bottom materials.

Features/Benefits

Magnesium aluminate (MgAl2O4) has a good lattice matching with epitaxial silicon thin layer.

The self-doping of aluminum atoms in the epitaxial silicon thin layer is small, the thermal stability is good, and the expansion coefficient of silicon is relatively close, the hardness is small, the processing performance is better, etc.

-

Growth Method

Czochralski

Crystal Structure

Cubic

Lattice Constant

a=8.085Å

Melting Point

2130℃

Density

3.64 (g/cm3)

Mohs Hardness

8 (mohs)

Color

White transparent

Thermal Expansion

7.45×10-6 /K

Dimension

10x3mm,10x5mm,10x10mm,15x15mm,20x15mm,20x20mm

Ф1″,Ф2″,

Thickness

0.5mm,1.0mm

Polishing

One side or two sides

Orientation

<100>、<110>、<111>±0.5º

Crystal Plane Orientation Accuracy

±0.5°

Edge Orientation Accuracy

2°(Special requirements can reach within 1°)

Bevel Wafer

According to specific requirements, wafers with edge-oriented crystal planes inclined at a specific angle (inclination angle 1°-45°) can be processed.

Surface Roughness

Ra≤5Å(5×5µm)

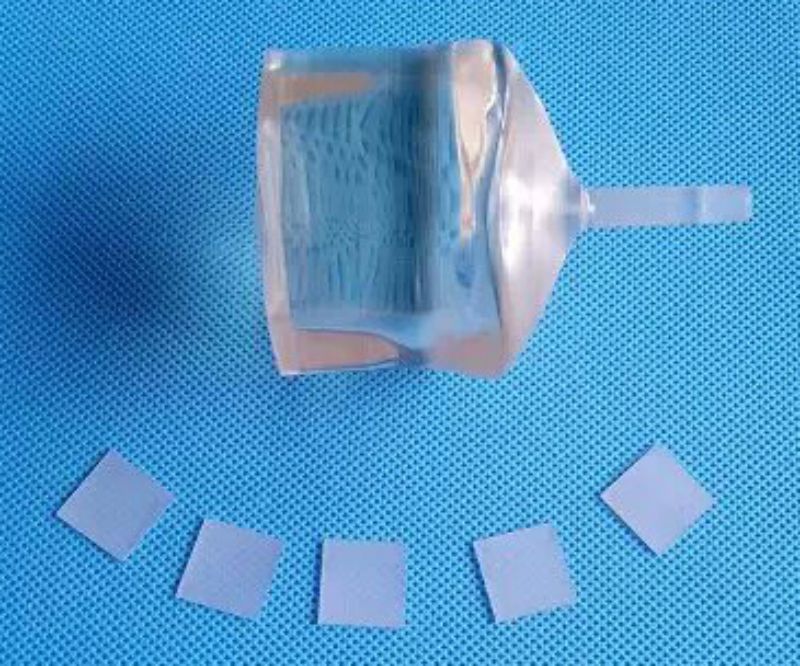

Package

Class 100 clean bag, Class 1000 super clean room

-

Dimension

10x3mm,10x5mm,10x10mm,15x15mm,20x15mm,20x20mm

Ф1″,Ф2″

Thickness

0.5mm,1.0mm